The importance of vacuum valves in vacuum systems

Release time:

2023.03.11

Sharing:

In a vacuum system, the vacuum system components used to change the direction of airflow, adjust the size of airflow, cut off or connect to pipelines are called vacuum valves.

In a vacuum system, the vacuum system components used to change the direction of airflow, adjust the size of airflow, cut off or connect to pipelines are called vacuum valves.

1、 The importance of vacuum valves in vacuum systems

1. Power switch air supply

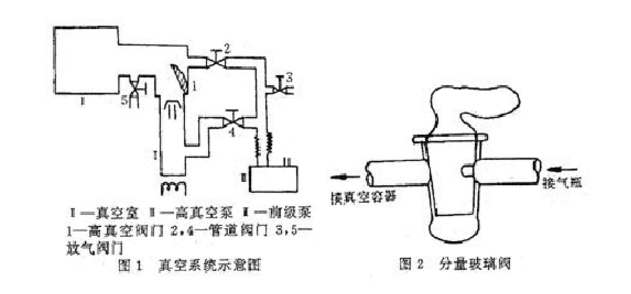

As shown in Figure 1, when valves 1 and 4 are closed and valve 2 is opened, the mechanical vacuum pump III vacuum packs container I, and the airflow flows through the pre vacuum extraction pipeline; When valve 2 is closed and valve 4 is opened, the vacuum pump can vacuum pack the diffusion pump separately; When valve 1 and valve 4 are opened at the same time, the diffusion pump and vacuum pump can work simultaneously to pump the container, and at this time, the airflow flows through the diffusion pump. From this, it can be seen that the importance of gate valves in such operations is to switch on the power supply and change the airflow path;

2. Control airflow size

Adjust the vacuum value In Figure 1, adjust the opening angle of the one-way valve of valve 1 to adjust the air flow through the pipeline; Close valve 2 and valve 4, and according to exhaust valve 3, air can be released into the channel of vacuum pump III; Adjust the vacuum value in the container according to exhaust valve 5;

3. Quantitative Analysis Boost

As shown in Figure 2 below, there is a small hole of a certain size in the plunger pump of the laminated glass valve. When the small hole is turned to the right and connected with the liquefied gas cylinder, the small hole can be filled with high-pressure air; When they are connected to the vacuum pump container on the left side, a certain volume of high-pressure air is also put into the container, which also plays a quantitative analysis of the pumping effect.

2、 The driving forms of vacuum valves mainly include the following methods

1. Manual

Manual vacuum valves are suitable for small and automated vacuum pumps, and are often used in experimental equipment;

2. Magnetic mobile

Magnetic movable vacuum valves are made by magnetizing the iron core with direct current or alternating current, completing the flow coil posture to drive the valve plate for fitness exercise. It is more commonly used for cut-off valves, exhaust valves, etc. in low vacuum pipelines due to the limited arrangement of the new stroke of the streamline coil, small specifications, and fast posture. Both magnetic movable vacuum valves and pneumatic vacuum valves are suitable for defensive field closing valves;

3. Pneumatic

Pneumatic vacuum valves are driven by air compression, with a compact structure and fast power switch. They are mainly used for long-distance operation in large and medium-sized vacuum technology, as well as the application of complex and multi gate vacuum systems. However, due to the need for a separate pneumatic valve, it is not suitable for use in small vacuum systems;

4. Electric and hydraulic

Electric vacuum valve refers to a vacuum valve driven by a motor, while oil pressure type drives the vacuum valve based on the pressure of liquid such as oil. These two types of vacuum valves require high-power vacuum valves, which are commonly used in large and medium-sized industrial production and highly automated vacuum systems.

Other news

We have passed the ISO9001:2015 international quality system certification and are a member of the China Vacuum Equipment Industry Association, a group member of the China Vacuum Society, a quality management unit in Ningbo City, and a three-level enterprise (machinery) for safety production standardization.

2023-03-11

Ningbo Instrument Valve Factory Conducts Outdoor Expansion Training for Employees

On the morning of May 22, 2022, facing the booming sunrise and accompanied by laughter, the one-day outdoor expansion activity of Ningbo Instrument Valve Factory was kicked off at Jiuchengyan Outdoor Expansion Training Base. All participants were divided into three groups, and a team leader and a deputy team leader were recommended and selected from their respective teams. After everyone gathered their ideas, they developed a highly creative team name and resounding slogan: Flame Team, Star Dream Team, and Surpass Team. This slogan is not just a slogan, but will also lead everyone to constantly strive and strive for it in the upcoming expansion training and competition.

2023-03-11

Current Status and Development Prospects of Vacuum Valve Standards

The countries with advanced vacuum valve technology in the world mainly include Russia, the United States, France, the United Kingdom, Germany, Japan, etc. From the early 20th century to the present, the varieties and specifications of vacuum valves in these countries have developed rapidly. Major vacuum equipment manufacturers in the world, such as Balzais, Raybold Hylas, Western European Nuclear Center and German Institute of Electronic synchrotron, are all professional manufacturers of vacuum valves and can develop various vacuum valves according to international standards.

2023-03-11

The importance of vacuum valves in vacuum systems

In a vacuum system, the vacuum system components used to change the direction of airflow, adjust the size of airflow, cut off or connect to pipelines are called vacuum valves.